The demographic change and the high number of work-related musculoskeletal conditions make an analysis of workplaces in production systems regarding the physical and psychological strain on employees more and more important.

Our research group works on numerous industrial projects for the evaluation and planning of workplaces. In the process, work systems in production, logistics and services are systematically analysed and ergonomically designed. Screening methods, measuring methods such as motion capture or electromyography as well as force measurements are used for this purpose. Additionally, the simulation and computer-aided planning of manual or semi-automated workstations is playing an increasingly important role.

Reference Projects

In order to keep employees in automotive assembly healthy and to be able to deploy them on the assembly line throughout their working lives, the research project “Von der Linie in Rente” in cooperation with Audi AG aims to identify potential for maintaining human performance, derive measures and implement them in pilot areas.

IAD is involved in the EU project FELICE (Flexible assembly manufacturing with human-robot collaboration and digital twin models) in the design of the adaptive workstation and human-robot collaboration, as well as in the evaluation of ergonomically designed solutions.

The Mittelstand-Digital Zentrum Darmstadt network supports small and medium-sized enterprises in the implementation of Industrie 4.0 as well as topics in the field of future AI technology in their companies by offering free information events, workshops and training courses.

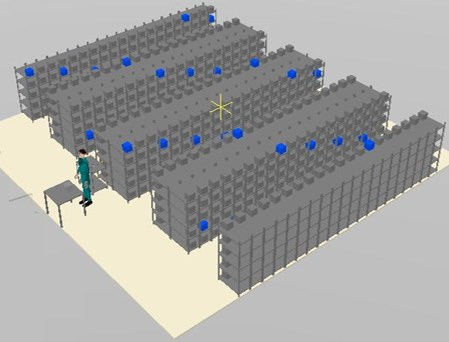

Despite increasing automation, work processes in warehouses are still characterized by manual material handling, such as lifting and carrying heavy loads or repetitive movements of the upper extremities. This can lead to high physical work load on the corresponding employees and ultimately to the development of musculoskeletal diseases.

The Project aimed to create design guidelines for a goods-to-person picking station from an ergonomic point of view.

The aim of this research project is therefore the integration of ergonomic aspects into planning concepts for commissioning in order to reduce the physical load while maintaining the efficiency and quality of commissioning.

The aim of the project was to provide ergonomic support and advice to the project partner on ergonomic issues relating to the introduction of lifting aids.

One of the main research and innovation priorities of the European Factories of the Future Research Association (EFFRA) is human-centered manufacturing: ‘Human-centricity’ will be needed in factories of the future in order to increase flexibility, agility, and competitiveness.

U-line assembly systems are workstations which are arranged in the form of a U according to the one-piece flow concept. These are hybrid systems in which automated processes are supplemented by manual activities. Depending on the job situation, one or more employees are flexibly deployed in U-lines. Intensive manual work in U-lines can lead to musculoskeletal disorders of the upper extremities and shoulder belt. This depends essentially on the work design. In U-lines, these include short movement cycles with highly dynamic and fine-motor finger-hand and arm movements, for example. U-lines can also cause increased strain on the lower extremities. Due to the circularity of the working persons in U-line assembly systems, lateral steps and rotational movements in the lower back area can occur, representing a significantly different stress pattern compared to “conventional" walking.

As a result of demographic change trade labor is facing some difficult challenges, however there is possibility in this area for creative solutions for the promotion of healthy working conditions. This may assist the employee retention and recruitment, which are seen as essential factors in the demographic orientation of small businesses.

The Institute of Ergonomics of the Technische Universität Darmstadt would like to, in cooperation with the Association of Hessian Chambers of Crafts (JV), the Federal Training Centre of the carpentry and finishing trades (BuBiZA), the Landesinnungsverband the roofing trade Hesse and the Association of color design and building protection Hesse, make a contribution to assist in the demographics-oriented design of these establishments.