Background

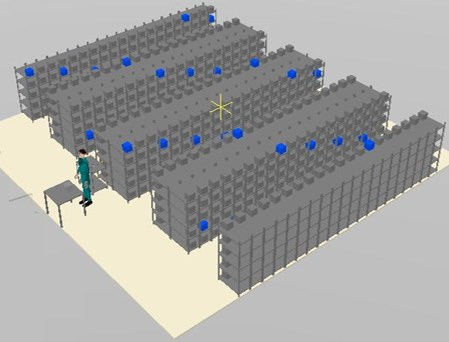

Despite increasing automation, work processes in warehouses are still characterized by manual material handling, such as lifting and carrying heavy loads or repetitive movements of the upper extremities. This can lead to high physical work load on the corresponding employees and ultimately to the development of musculoskeletal diseases.

However, planning concepts for warehouse processes used in practice continue to take almost exclusively economic parameters into account. Ergonomic parameters are largely ignored (Grosse et al., 2015).

The IGF project (No. 21292 N) of the Forschungsgemeinschaft lntralogistik/Fördertechnik und Logistiksysteme e.V. – IFL, Lyoner Straße 18, 60528 Frankfurt am Main, was carried out by the Federal Ministry of Economics via the AiF as part of the program for the promotion of industrial community research (IGF) and energy promoted on the basis of a decision of the German Bundestag.

Goals

The aim of this interdisciplinary project, which is carried out in cooperation with the Department of Production and Supply Chain Management at TU Darmstadt (Prof. Glock), is to bring together economic and ergonomic parameters in planning concepts for manual warehouse processes. These concepts are intended to ensure both ergonomic and economically competitive warehouse processes.

Work load (motion capture, screening methods) and physical strain analyzes (EMG, questionnaires) are carried out on site. These measured parameters are then used to develop integrative ergonomic key figures for warehouse activities. These are converted into mathematical optimization models and combined with economic key figures.

Results

- Numerical experiments with the developed integrative optimization model

- Effects of holistic planning concepts for manual warehouse processes

- Quantification of the interactions between economic and ergonomic variables

- Derivation of comprehensive guideline for ergonomic work design in warehouses